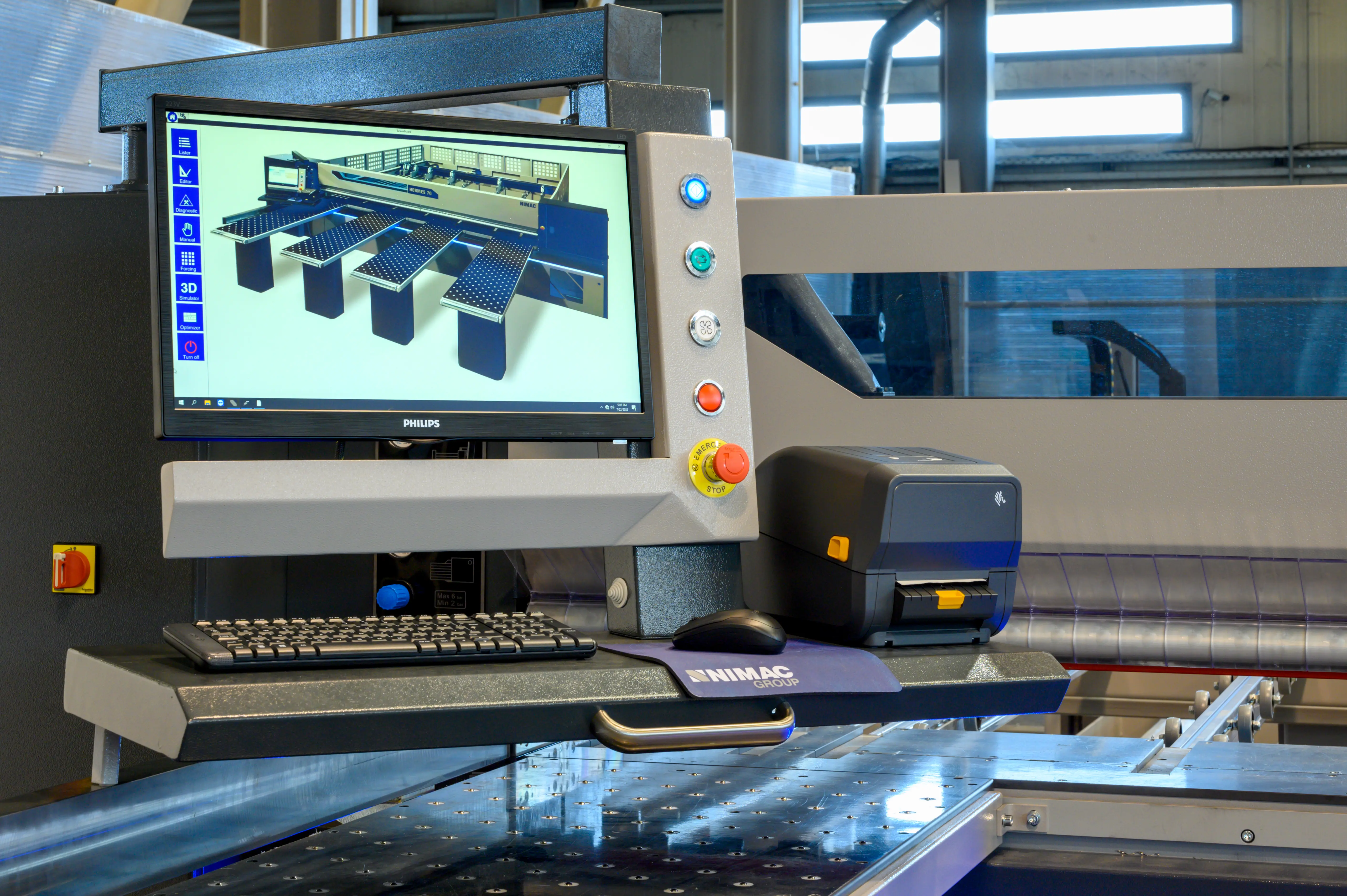

Easy use by powerful Software

• Built-in cutting optimizer software

• Powerful controller TPA including the most advanced software with 3D real time graphic simulation with messages for the operator

• Easy to use with optimized functions

Industrial beam saw with automatic rear loading platform

Maximize the quantity of the cutting panels by one operator

| Cutting length | 3200 mm, 3800 mm, 4400 mm |

| Blade projection | 105 mm |

| Main saw diameter | 355 mm |

| Scoring saw diameter | 160 mm |

| Main motor power | 10 hp, 15 hp, 20 hp |

| Scoring saw power | 2 hp |

| Saw carriage speed | 5-120 m/min |

| Pusher's travel speed | 0-60 m/min |

| Automatic side aligner | 50-1100 mm |

| Controller | TPA |

| Optimizer software | OPTICUT Lite |

| 3D visualization software with processing | Beamboard |

| PC with accessories | W11, SSD, WiFi, LAN |

| Monitor | DELL 24’’ |

| Pressure beam with special clamp slots (Sheets remain firmly held until the final cut) | |

| Quick blade change system | |

| Scoring with micro-adjustment capability both vertically and horizontally | |

| CE safety rules. Rear safety fence and hands protection curtain | |

| Electrical Control Panel: Featuring EtherCat technology | |

| Magnetic Tape: (Pulse generator - contactless system) for precise guide measurement | |

| Remote Support: Available via internet connection | |