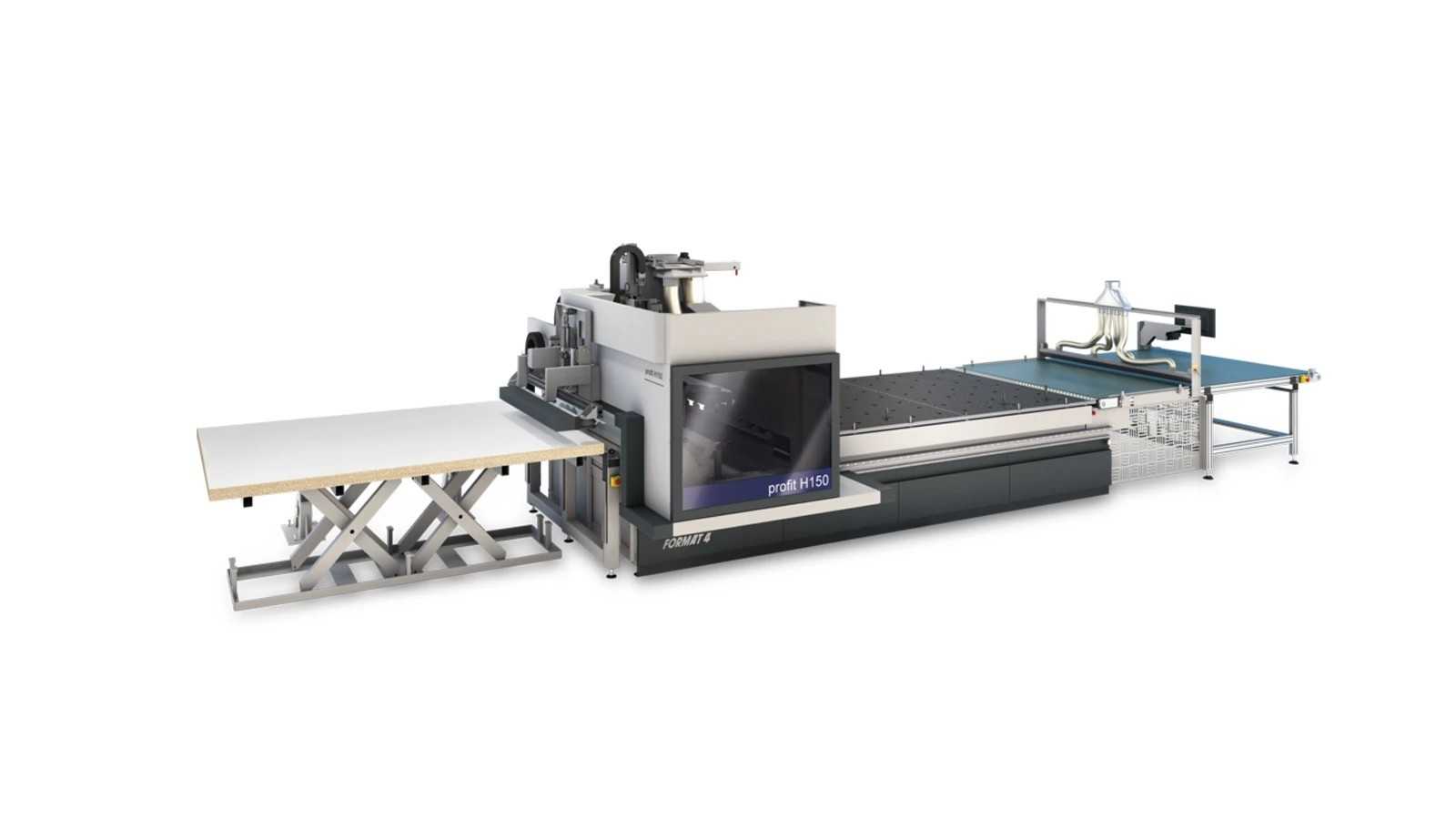

profit H150

5-axis Nesting CNC machining centre profit H150

- • Powerful electrospindle with 5 axes for unlimited processing possibilities

- • Intelligent SMART ZONING vacuum management system with pendulum operation

- • Four sizes for every workshop: 16.38, 22.32, 22.43 and 22.61

- • Front stop row set back for unrestricted machining of individual workpieces with a 3-4 or 5-axis spindle

- • Large Z passage size of 200 mm offers flexible machining of high workpieces.

- • Loading and unloading units as well as automatic labelling on the loading table

- • Up to 36 tool positions

- • F4®Solutionsready

The new Nesting-CNC profit H150 from Format4 is the perfect panel cutting, drilling and milling centre for future-proof carpentry and joiner's workshops. Entire custom-made furniture with all holes, grooves and connections are produced in one single operation. The latest nesting technologies ensure the highest possible material and time savings. The profit H150 can be extended to full automation with different loading and unloading solutions, thus achieving maximum productivity.

Four sizes (16.38, 22.32, 22.43 & 22.61) with integrated SMART ZONING vacuum management, high-end automation levels, above-average drill heads, new safety concepts and much more. The high-performance Format4 high-tech 5-axis moulder spindle was developed especially for the increased demands of professional woodworking and enables individual workpiece design in record time. For the unrestricted use of the 5-axis spindle, a set-back row of stops is available. A large Z passage size of 200 mm offers flexible machining of high workpieces.

With the standard tool changer and optionally available moving rotary tool changer as well as the pick-up space for a large saw blade, a total number of up to 36 tool places are available. The automatic pre-labelling on the loading table minimizes sources of error and at the same time reduces the processing times.

With the performance package, the CNC control makes the highest industry standard possible. Different optimisation levels ensure shorter process times, different milling results and increased comfort in CNC machining.